Saif

Senior Member

- Joined

- Jan 24, 2024

- Messages

- 15,405

- Nation

- Axis Group

RMG Businesses eye opportunities amid US-China trade war

The country’s readymade garment manufacturers said that Bangladesh needs to improve and stabilise its law-and-order situation and business atmosphere to seize the opportunities emerging from the ongoing US-China trade tensions.

www.newagebd.net

www.newagebd.net

RMG Businesses eye opportunities amid US-China trade war

Saddam Hossain 15 February, 2025, 23:04

A file photo shows workers sewing clothes at a readymade garment factory in Narayanganj. | New Age photo

The country’s readymade garment manufacturers said that Bangladesh needs to improve and stabilise its law-and-order situation and business atmosphere to seize the opportunities emerging from the ongoing US-China trade tensions.

After assuming office as the president of the United States, ‘tariff man’ Donald J Trump has implemented a series of executive order tariffs on its key trading partners, including Canada, Mexico, and China, as part of its broader trade policy agenda.

Recently, he imposed additional 25 per cent tariffs on Canadian and Mexican imports and 10 per cent tariffs on Chinese goods including textiles which may shift the trade dynamics between these two economic giants.

The industry insiders said that as Chinese exports to the US become more expensive due to tariffs, global buyers will shift their orders to other low-cost countries.

In this regard, Bangladesh will be a natural choice along with other competitors with its unshakable RMG sector.

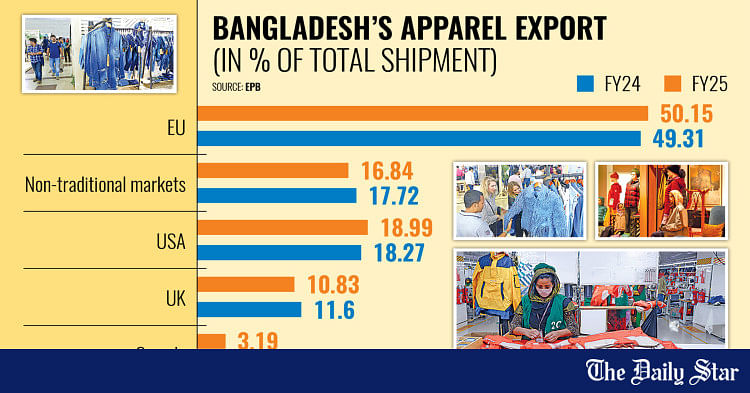

The US is the single largest export destination for Bangladeshi RMG shippers, who exported apparel items worth $7.34 billion in 2024.

Moreover, Bangladesh secured the second-largest source of US apparel imports, with a 9.26 per cent market share.

China remains the market leader in the US, with a market share of 20.83 per cent, and the country exports apparel items worth $16.51 billion.

Industry insiders said that the country’s apparel exports to the US are stable thanks to competitive pricing, sustainability, and compliance with international labor and environmental standards.

If Bangladesh addresses the remaining challenges, it could emerge as a key beneficiary of this geopolitical shift.

Talking to New Age, Faruque Hassan, former president of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), said that the law-and-order situation is improving gradually.

“But we need more improved and stable situation. The government should work stop shutting down of any factories. They have to provide policy supports in this regard,” he added.

He also said that the government has to solve the ongoing issues related to gas and energy. Interruption in gas and energy supply may hinder the golden opportunity.

“We also need to resolve the issues related to bonds, customs, and NBR. The corruption didn’t stop yet which is concerning for us. We hope the interim government can take many drastic decisions without any political burden. We urge the government to do this in the sake of country’s economy,” he added.

He also said that buyers have confidence in Bangladesh due to ethical and eco-friendly production practices. So, the manufacturers and government should work together to retain this confidence by maintaining a good business atmosphere, sustainable production, and a proper work environment.

Currently, Bangladeshi apparel exporters face a tariff of more than 15 per cent when exporting to the US, whereas Chinese exporters face 25 per cent.

Mohiuddin Rubel, former director of the BGMEA, told New Age that due to high production costs, apparel businesses in China have been gradually shifting.

“However, Trump’s tariff policy is making it earlier. Our competitors are also as same as our position to grab them, we have to address the challenges to grab these,” he added.

An improved business atmosphere and security will play crucial roles in raising businesses and attracting foreign direct investment.

“In the last fiscal, the FDI dropped by 8.8 per cent. Moreover, Bangladesh ranked 12th most corrupted country in 2024. We have to work hard to remove corruption to do better business and to attract more FDI,” he added.

He also said that the country should immediately focus on issues like infrastructure, fuel, and energy.

The manufacturers also stated the country must diversify its product basket by shifting its focus from T-shirts and sweaters and branching out into higher-value items.

Saddam Hossain 15 February, 2025, 23:04

A file photo shows workers sewing clothes at a readymade garment factory in Narayanganj. | New Age photo

The country’s readymade garment manufacturers said that Bangladesh needs to improve and stabilise its law-and-order situation and business atmosphere to seize the opportunities emerging from the ongoing US-China trade tensions.

After assuming office as the president of the United States, ‘tariff man’ Donald J Trump has implemented a series of executive order tariffs on its key trading partners, including Canada, Mexico, and China, as part of its broader trade policy agenda.

Recently, he imposed additional 25 per cent tariffs on Canadian and Mexican imports and 10 per cent tariffs on Chinese goods including textiles which may shift the trade dynamics between these two economic giants.

The industry insiders said that as Chinese exports to the US become more expensive due to tariffs, global buyers will shift their orders to other low-cost countries.

In this regard, Bangladesh will be a natural choice along with other competitors with its unshakable RMG sector.

The US is the single largest export destination for Bangladeshi RMG shippers, who exported apparel items worth $7.34 billion in 2024.

Moreover, Bangladesh secured the second-largest source of US apparel imports, with a 9.26 per cent market share.

China remains the market leader in the US, with a market share of 20.83 per cent, and the country exports apparel items worth $16.51 billion.

Industry insiders said that the country’s apparel exports to the US are stable thanks to competitive pricing, sustainability, and compliance with international labor and environmental standards.

If Bangladesh addresses the remaining challenges, it could emerge as a key beneficiary of this geopolitical shift.

Talking to New Age, Faruque Hassan, former president of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), said that the law-and-order situation is improving gradually.

“But we need more improved and stable situation. The government should work stop shutting down of any factories. They have to provide policy supports in this regard,” he added.

He also said that the government has to solve the ongoing issues related to gas and energy. Interruption in gas and energy supply may hinder the golden opportunity.

“We also need to resolve the issues related to bonds, customs, and NBR. The corruption didn’t stop yet which is concerning for us. We hope the interim government can take many drastic decisions without any political burden. We urge the government to do this in the sake of country’s economy,” he added.

He also said that buyers have confidence in Bangladesh due to ethical and eco-friendly production practices. So, the manufacturers and government should work together to retain this confidence by maintaining a good business atmosphere, sustainable production, and a proper work environment.

Currently, Bangladeshi apparel exporters face a tariff of more than 15 per cent when exporting to the US, whereas Chinese exporters face 25 per cent.

Mohiuddin Rubel, former director of the BGMEA, told New Age that due to high production costs, apparel businesses in China have been gradually shifting.

“However, Trump’s tariff policy is making it earlier. Our competitors are also as same as our position to grab them, we have to address the challenges to grab these,” he added.

An improved business atmosphere and security will play crucial roles in raising businesses and attracting foreign direct investment.

“In the last fiscal, the FDI dropped by 8.8 per cent. Moreover, Bangladesh ranked 12th most corrupted country in 2024. We have to work hard to remove corruption to do better business and to attract more FDI,” he added.

He also said that the country should immediately focus on issues like infrastructure, fuel, and energy.

The manufacturers also stated the country must diversify its product basket by shifting its focus from T-shirts and sweaters and branching out into higher-value items.