- Copy to clipboard

- Thread starter

- #31

Fresh focus on jute packaging

The directive of the interim government to halt use of poly bags in the super shops looks like a first step in materialising the mandatory jute packaging law that seemingly lost its urgency despite sporadic moves to enforce it in the past. Obviously, the only viable alternative to poly bags is jute

Fresh focus on jute packaging

Wasi Ahmed

Published :

Sep 17, 2024 22:08

Updated :

Sep 17, 2024 22:08

The directive of the interim government to halt use of poly bags in the super shops looks like a first step in materialising the mandatory jute packaging law that seemingly lost its urgency despite sporadic moves to enforce it in the past. Obviously, the only viable alternative to poly bags is jute-made packaging stuffs.

Environment, forest and climate change adviser to the interim government announced the ban of polythene and polypropylene shopping bags across all superstores in the country starting October 1. She made the announcement during a meeting with stakeholders. A press release issued in this regard says the government will require superstores to offer jute and fabric bags as eco-friendly alternatives. There will also be an emphasis on engaging young people and students in the initiative. A detailed action plan has reportedly been formulated to enforce the upcoming ban, including steps to raise public awareness through a nationwide media campaign. To ensure the availability of jute and fabric shopping bags, the Ministry of Textiles and Jute will hold meetings with superstore operators within a week to secure a steady supply of alternative bags.

The decision, one may recall, is not new. A ban on the use of poly bags or other non-biodegradable materials for packaging was imposed as early as 2002, first of its kind in the world to curb pollution and water-logging, and also as a breakthrough in the increased consumption of jute materials domestically. Following the restrictions, there was a surge for a while in the use of paper and other biodegradable materials (in the absence of sufficient jute bags) for packaging, and no doubt it did signal a shift that further needed to firm up actions in a sustained manner.

Unfortunately, that did not happen. What is surprising is that the authorities had backtracked from the restrictions on the use of polythene or synthetic materials for packaging all kinds of groceries in the shops, kitchen markets and super stores. So, what promised like a good prospect had gone into oblivion. There were quite a few moves including framing of a law, and a verdict by the Appellate division of the High Court, to make jute packaging mandatory in respect of a variety of commodities. These, though reinforced later by law enforcers' drives in the market places, fell flat as the then government's effort to replace packaging by plastic or synthetic materials with jute sacks/bags remained unheeded.

The law on the mandatory use of jute sacks was enacted in 2010, but in the absence of rules to be followed, it was largely ignored. Subsequently, a set of rules for implementation of the law had been formulated which among others sought to ensure use of jute sacks in packaging a number of products, including rice. The ministry of textiles and jute on September 26, 2013 issued a Circular on mandatory use of jute bags for commercial packaging of rice by the private rice millers, husking millers and rice traders. It had also asked them to stop using polythene/plastic bags by December 2014. But the millers and traders did not comply with its instructions. Subsequently, some rice mill owners filed a writ petition with the High Court seeking a stay order on the enforcement of the Circular. In response, the High Court in an ad-interim order stayed the government directive relating to mandatory jute-bag use. However, following the government's move in the form of Appeal, the Appellate Division vacated the stay order upholding the government' directive on mandatory jute packaging.

It may be noted that while making jute packaging of rice mandatory, the directive of the government had included a number of other products. These were - paddy, wheat, maize, fertiliser, sugar, spices, turmeric, onion, ginger, garlic, coriander, pulses, potato, flour, crude flour (ata) and rice bran. Later, two other products-poultry and fish feed were also included in the list.

It was not the lack of compliance alone but dearth of sufficient and cost-effective jute bags/sacks that stood in the way of enforcement. Now that the interim government is set to revive the issue-- much to the relief of conscious citizens, it is important to go by phases. Starting with the super stores, the ban should gradually extend to other areas such as kitchen markets, shops, restaurants. Eventually, it would be important to make use of jute sacks compulsory for packaging food grains.

Packaging of food grains has for long been viewed crucially important for a variety of reasons. In the wake of the global campaign on the use of environmentally friendly, biodegradable natural materials in as many areas as possible, it is highly likely that Bangladesh being the producer of world's finest variety of natural fibre - jute, would make the best use of it to draw benefits in tangible economic terms. Experts are of the opinion that if enforced strictly, use of jute sacks will no doubt go beyond environmental security as it will ensure better price for jute growers and jute goods manufacturers, who are currently facing a lingering slump in view of receding demand.

It is expected that the authorities will take lesson from the past. The success of the move depends on availability of biodegradable materials and enforcement of the law. As the authorities will proceed to bring other areas under non-polythene packaging, shortage of required materials, say jute bags/sacks, may be a problem, which had been the case in the past. It is thus important to ensure availability first.

Wasi Ahmed

Published :

Sep 17, 2024 22:08

Updated :

Sep 17, 2024 22:08

The directive of the interim government to halt use of poly bags in the super shops looks like a first step in materialising the mandatory jute packaging law that seemingly lost its urgency despite sporadic moves to enforce it in the past. Obviously, the only viable alternative to poly bags is jute-made packaging stuffs.

Environment, forest and climate change adviser to the interim government announced the ban of polythene and polypropylene shopping bags across all superstores in the country starting October 1. She made the announcement during a meeting with stakeholders. A press release issued in this regard says the government will require superstores to offer jute and fabric bags as eco-friendly alternatives. There will also be an emphasis on engaging young people and students in the initiative. A detailed action plan has reportedly been formulated to enforce the upcoming ban, including steps to raise public awareness through a nationwide media campaign. To ensure the availability of jute and fabric shopping bags, the Ministry of Textiles and Jute will hold meetings with superstore operators within a week to secure a steady supply of alternative bags.

The decision, one may recall, is not new. A ban on the use of poly bags or other non-biodegradable materials for packaging was imposed as early as 2002, first of its kind in the world to curb pollution and water-logging, and also as a breakthrough in the increased consumption of jute materials domestically. Following the restrictions, there was a surge for a while in the use of paper and other biodegradable materials (in the absence of sufficient jute bags) for packaging, and no doubt it did signal a shift that further needed to firm up actions in a sustained manner.

Unfortunately, that did not happen. What is surprising is that the authorities had backtracked from the restrictions on the use of polythene or synthetic materials for packaging all kinds of groceries in the shops, kitchen markets and super stores. So, what promised like a good prospect had gone into oblivion. There were quite a few moves including framing of a law, and a verdict by the Appellate division of the High Court, to make jute packaging mandatory in respect of a variety of commodities. These, though reinforced later by law enforcers' drives in the market places, fell flat as the then government's effort to replace packaging by plastic or synthetic materials with jute sacks/bags remained unheeded.

The law on the mandatory use of jute sacks was enacted in 2010, but in the absence of rules to be followed, it was largely ignored. Subsequently, a set of rules for implementation of the law had been formulated which among others sought to ensure use of jute sacks in packaging a number of products, including rice. The ministry of textiles and jute on September 26, 2013 issued a Circular on mandatory use of jute bags for commercial packaging of rice by the private rice millers, husking millers and rice traders. It had also asked them to stop using polythene/plastic bags by December 2014. But the millers and traders did not comply with its instructions. Subsequently, some rice mill owners filed a writ petition with the High Court seeking a stay order on the enforcement of the Circular. In response, the High Court in an ad-interim order stayed the government directive relating to mandatory jute-bag use. However, following the government's move in the form of Appeal, the Appellate Division vacated the stay order upholding the government' directive on mandatory jute packaging.

It may be noted that while making jute packaging of rice mandatory, the directive of the government had included a number of other products. These were - paddy, wheat, maize, fertiliser, sugar, spices, turmeric, onion, ginger, garlic, coriander, pulses, potato, flour, crude flour (ata) and rice bran. Later, two other products-poultry and fish feed were also included in the list.

It was not the lack of compliance alone but dearth of sufficient and cost-effective jute bags/sacks that stood in the way of enforcement. Now that the interim government is set to revive the issue-- much to the relief of conscious citizens, it is important to go by phases. Starting with the super stores, the ban should gradually extend to other areas such as kitchen markets, shops, restaurants. Eventually, it would be important to make use of jute sacks compulsory for packaging food grains.

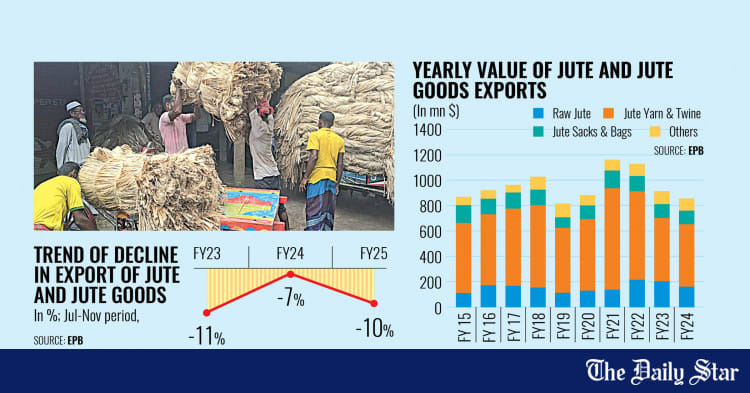

Packaging of food grains has for long been viewed crucially important for a variety of reasons. In the wake of the global campaign on the use of environmentally friendly, biodegradable natural materials in as many areas as possible, it is highly likely that Bangladesh being the producer of world's finest variety of natural fibre - jute, would make the best use of it to draw benefits in tangible economic terms. Experts are of the opinion that if enforced strictly, use of jute sacks will no doubt go beyond environmental security as it will ensure better price for jute growers and jute goods manufacturers, who are currently facing a lingering slump in view of receding demand.

It is expected that the authorities will take lesson from the past. The success of the move depends on availability of biodegradable materials and enforcement of the law. As the authorities will proceed to bring other areas under non-polythene packaging, shortage of required materials, say jute bags/sacks, may be a problem, which had been the case in the past. It is thus important to ensure availability first.