Top 10 foreign companies that source garments from Bangladesh

Masud Milad &

Shuvonkar Karmokar

Published: 23 Dec 2024, 14: 39

RMG workers at a factory File photo

Thousands of foreign buyer companies and brands purchase ready-made garments from Bangladesh. Among them, the top ten account for nearly 29 per cent of the exported ready-made garments. Sweden's multinational retail company H&M leads the list of buyers, followed by Spain's Inditex and Ireland's Primark in second and third places, respectively. In the outgoing fiscal year, these three companies together purchased nearly $6 billion (600 crore USD) worth of ready-made garments from Bangladesh.

This list of top garment buyers for the 2023-24 fiscal year was compiled by Prothom Alo after analysing data from the National Board of Revenue (NBR) and buyer information. The analysis covered approximately 2.1 million shipments exported in the previous fiscal year, including details of imports by both parent companies and their affiliates. The data included information from 1,264 affiliate companies of the top 10 buyers, but did not account for garments purchased through buying houses or agents.

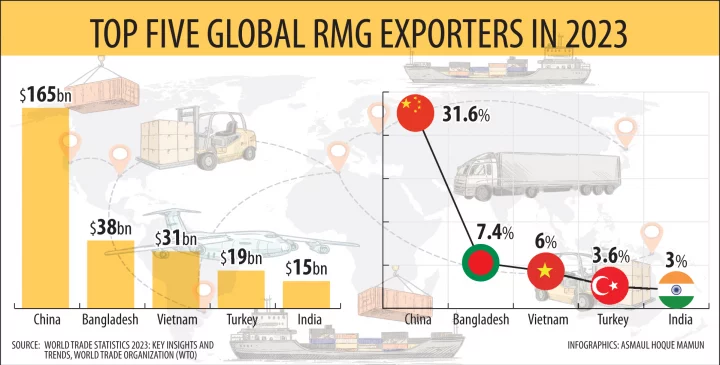

According to NBR data, Bangladesh exported $3.637 billion worth of ready-made garments to thousands of buyers in the last fiscal year. Of this, the top ten buyers purchased garments worth $1.05 billion, which accounts for 29 per cent of total exports. These multinational companies primarily sell the garments in major markets, with the United States being the largest market for Bangladeshi garments.

After H&M, Inditex, and Primark, the remaining buyers in the top ten list include Bestseller from Denmark, Marks & Spencer from the UK, C&A from the Netherlands, Uniqlo from Japan, LPP from Poland, Next from the UK, and Pepco from Poland. One of the world's largest buyers, Walmart, purchased $400 million worth of garments from Bangladesh in the past fiscal year. However, Walmart also buys a large amount through buying houses, which could not be tracked. The US company has chosen not to disclose its purchasing information, meaning it did not make it to the top ten list.

When asked about this, Walmart's Director of Corporate Affairs (Global Communication and Sourcing), Blair Cromwell, stated in an email that they do not publicly release statistics. However, he emphasized that Bangladesh has been a crucial supplier for Walmart for many years, and the strategy for purchasing garments from Bangladesh remains unchanged.

Bangladesh's factories mainly export low-cost garments, which is why the top ten multinational companies typically purchase relatively inexpensive products from the country. On average, these companies pay $3 per piece of clothing. Among the top ten buyers, Uniqlo paid the highest, at $5.41 per piece.

No direct data was found for high-end brands like Louis Vuitton, Dior, Chanel, Gucci, or US's Nike purchasing garments from Bangladesh in the last fiscal year. However, Adidas, a German sportswear brand, did buy garments from Bangladesh, spending $25.6 million. The average price per garment was $23.5 (Tk 2,834). Though in smaller quantities, other well-known buyers like Ralph Lauren from the United States and Lululemon from Canada also sourced garments from Bangladesh. These luxury brands purchase limited garments, with export prices ranging from $300 to $500 per piece.

Prothom Alo has contacted senior executives from five of the top ten buyers, all of whom confirmed the accuracy of the direct garment purchase data, although they declined to comment officially due to company headquarters' restrictions.

Top buyer H&M

H&M is the largest buyer of Bangladeshi-made garments. In the last fiscal year, this company sourced "Made in Bangladesh" garments from over 1,000 outlets across 44 countries. While people in 60 countries can purchase H&M garments online, the highest sales of Bangladesh-made garments are in Poland, Germany, and the United States.

Last year, H&M bought $259 million worth of garments from Bangladesh. The company sourced these garments from over 200 factories in the country. Every day, H&M's garments are part of the shipments exported from Bangladesh. On average, 2,042 shipments of H&M products are loaded onto ships or planes daily. These shipments include clothing for people of all ages, from newborns to adults.

H&M, which started with a single store in 1947, now operates 4,298 sales centres worldwide. Last year, the company sold products worth $21.32 billion. The company is listed on the NASDAQ Nordic Exchange, and its main brands include H&M, Cos, Weekday, Monki, Cheap Monday, Afound, and & Other Stories.

According to H&M's published list, they source garments, home textiles, shoes, and cosmetics from 916 suppliers across 41 countries. H&M has been sourcing ready-made garments from Bangladesh for three decades and has been one of the leading buyers for many years. In the 2021-22 fiscal year, H&M purchased the most garments from Bangladesh, totaling $290 million. Although the amount slightly decreased the following year, they remain among the top buyers.

When contacted, H&M's Global Communications Press Officer and Communications Specialist Albin Nordin in an email told Prothom Alo, "Bangladesh is an extremely important garment-producing country for us. Since 1983, H&M Group has had a presence in Bangladesh with our own production office. Having a dedicated team in our key product-producing country is always advantageous."

When asked if they plan to expand their business in Bangladesh, he did not give a direct answer but mentioned, "Bangladesh is a very important market for us."

Inditex surpasses $2 billion in purchases

Inditex, the second-largest buyer of Bangladeshi-made garments, is a Spanish multinational company. They have been increasing their garment purchases from Bangladesh every year. Last year, they bought $2.18 billion worth of garments from Bangladesh. This is the first time they purchased garments worth more than $2 billion in a fiscal year.

Inditex ships garments to sales outlets in 13 countries, with Spain being the largest market, receiving $1.87 billion worth of garments. The company's main brands include Zara, Pull & Bear, Bershka, Stradivarius, Oysho, and Massimo Dutti. Their purchases from Bangladesh include everything from underwear to overcoats. The garments are supplied by 250 factories in Bangladesh.

Primark purchases low-cost garments

Primark, an Irish multinational retailer, is listed among the buyers of Bangladeshi-made garments who purchase over $1 billion million annually. Last year, the company bought $1.12 billion worth of garments from Bangladesh, making it the third-largest buyer.

Primark has 451 sales outlets in 17 countries. In the fiscal year ending in September, the company generated €9.44 billion in revenue. Primark's main markets are Europe and the United States. They purchase a significant portion of their garments for the UK market from Bangladesh.

A Primark official, speaking on the condition of anonymity, informed Prothom Alo that the company plans to expand its business in Bangladesh.

Bestseller purchases garments at $4.50 each

Bestseller, a Danish multinational company, is the fourth-largest buyer of Bangladeshi-made garments. Last year, they bought garments worth nearly $790 million from Bangladesh. The average price per piece was $4.66, the second-highest among the top ten buyers.

These garments were supplied by 95 factories in Bangladesh and are sold in 11 countries where Bestseller operates.

Marks & Spencer expands business

British multinational company Marks & Spencer (M&S) is the fifth-largest buyer of Bangladeshi-made garments. Last year, they purchased $780 million worth of garments, totaling 210 million pieces. The average price per garment was $3.74.

The main brands of the company are Marks & Spencer and Autograph. Ninety-one per cent of the garments bought from Bangladesh are sent to M&S's sales outlets in the UK. Last year, the company sourced garments from 51 factories in Bangladesh. Like other British brands, M&S is increasing its garment purchases from Bangladesh, according to a company official.

C&A sources half of its garments from Bangladesh

C&A, a retail company based in the Netherlands, has significantly increased its share of garments sourced from Bangladesh. In 2020, 36 per cent of their total garment purchases came from Bangladesh. By 2022, this figure had risen to 51 per cent. According to the company's sustainability report, C&A buys 13 per cent of its garments from China, the second-largest source.

Founded in 1841 by two brothers in the Netherlands, C&A is the sixth-largest buyer of Bangladeshi-made garments. Last year, they bought nearly $720 million worth of garments, totaling 20 million pieces. The average price per piece was $3.62, and the garments came from at least 50 factories in Bangladesh.

Uniqlo purchases expensive garments

Uniqlo, a Japanese multinational company, bought garments worth $715 million from Bangladesh last year, totaling 132.1 million pieces. The average price per garment was $5.41, the highest among the top ten buyers.

Uniqlo's parent company, Fast Retailing, operates seven brands, including Uniqlo, GU, Theory, and J Brand, with 3,595 sales outlets worldwide. The garments sourced from Bangladesh are sold in 24 countries. Last year, 26 factories in Bangladesh supplied garments to Uniqlo, with 32 per cent of the supply coming from Pacific Jeans Group.

LPP sources garments from 250 factories

Polish multinational company LPP purchased $654.4 million worth of garments from Bangladesh in the last fiscal year. These garments were supplied by nearly 250 factories in Bangladesh. LPP opened its branch office in Dhaka in 2015.

According to information on LPP's website, the company sells garments from its five brands in 40 countries worldwide. These brands are Reserved, Cropp, Mohito, House, and Sinsay.

Next purchases half a billion dollars' worth of garments

UK-based multinational company Next, which is 160 years old, buys half a billion dollars' worth of garments from Bangladesh each year. Last year, they purchased 160 million pieces of clothing worth $530 million, meaning Next paid an average of $3.24 per piece.

Pepco purchases low-cost garments

Polish multinational retailer Pepco purchases garments from Bangladesh at the lowest prices among the top buyers. In the last fiscal year, Pepco bought $460 million worth of garments, totaling 260 million pieces. The average price per garment was just under $1.75, the lowest among the top ten buyers.

Pepco operates over 4,500 sales outlets across 21 European countries. The main countries where Pepco sources its garments are Bangladesh, China, and India. The company markets garments under four brands: Pepco, Poundland, PGS, and Dealz.

When asked, Faruk Hassan, the former president of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), told Prothom Alo, "Bangladesh produces garments for over 1,000 buyer companies, both large and small. This is what strengthens our garment industry. Since, except for a few, most buyers source garments from Bangladesh, it can be considered a strong branding asset. In addition to garments, there is a great opportunity to sell other products from Bangladesh to these buyers."