Published: 00:00, Mar 08,2024

The root cause of why women are held back from becoming truly empowered anywhere needs to be addressed as well. Social change is required, and respect for gender, qualification, and education all need to come in a single package, writes Saira Rahman Khan

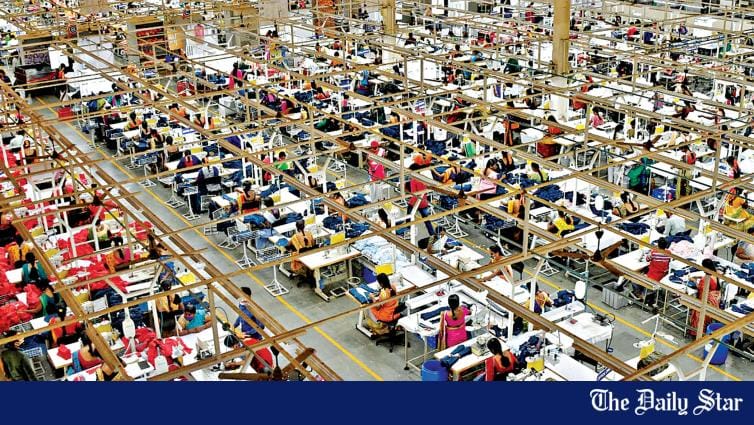

A VERY large number of women in Bangladesh have found employment in the readymade garment factories in Bangladesh, and there is little doubt that they have been seen as the success story for women’s empowerment in the country, supported by countless research and studies. To be empowered, women and girls must have the agency to use their rights, capabilities, resources, and opportunities to make strategic choices and decisions (UNICEF, 2017). Generally speaking, it is still a challenge for women from rural or poor economic conditions in Bangladesh to find ‘empowerment’. It is also seen that, despite the barriers, women are a part of the work and labour force of Bangladesh, especially in the RMG sector. Do these places of employment act as arenas of empowerment? According to UN Women, there were almost 5,000 ready-made garment factories in Bangladesh, contributing to the biggest export earning sector (80.7 per cent of the total export earnings) in the financial year of 2017 (UN Women, 2018). Women comprise 60–70 per cent of the RMG workforce, but with a low literacy level, little knowledge, and little control over their working conditions (UN Women, 2018).

In 2011, UN Women published a guideline on empowering women to participate in economic life in the workplace, market, etc. with the purpose of building strong economies. The guideline is called ‘The Women’s Empowerment Principles’ and consists of a set of principles for business offering guidance on how to empower women in the workplace, marketplace, and community. They are the result of a collaboration between the United Nations Entity for Gender Equality and the Empowerment of Women (UN Women) and the United Nations Global Compact. The principle’s emphasis is on the business case for corporate action to promote gender equality and women’s empowerment and is informed by real-life business practices and input gathered from across the globe.’ There are seven principles in total: Principle 1: Establish high-level corporate leadership for gender equality; Principle 2: Treat all women and men fairly at work — respect and support human rights and non-discrimination; Principle 3: Ensure the health, safety, and well-being of all women and men workers; Principle 4: Promote education, training, and professional development for women; Principle 5: Implement enterprise development, supply chain, and marketing practices that empower women; Principle 6: Promote equality through community initiatives and advocacy; and Principle 7: Measure and publicly report on progress to achieve gender equality. Have RMG industries adhered to these principles? Although all seven of the principles are vital for success, the focus of this paper will be on Principles 2, 3, and 4, as these seem to contain the most basic rights needed to provide empowerment opportunities for women workers in the RMG sector.

The second Women’s Empowerment Principle deals with the issues of fair treatment, non-discrimination, and respect for human rights. Islam (2018) has identified four types of gender-based discrimination in the RMG factory: gender division of labour, discrimination as regards promotions and service benefits, wage discrimination, and discrimination when in a leadership position. According to research conducted by the International Labor Organisation in 2020, 84 per cent of women workers in the RMG sector are in low grades, compared to 68 per cent of men. The research further found that from 2010 to 2018, the proportion of surveyed women in most managerial positions declined, and their overall average representation in such roles remained low and unchanged between 2010 and 2018 (approximately 9 percent). This indicates no improvements in enhancing women’s representation in managerial and leadership positions in the RMG sector in the past decade (ILO, 2020). An earlier 2018 study shows that the ratio of male to female professionals at the managerial and HR managerial levels is 190:1 and 176:17, respectively (CPD-RMG Study, 2017–2018). Thus portraying huge gender imbalances in these levels of RMG sectors. Women are further limited to ‘unskilled’ or’semi-skilled’ job categories in the garment factory; the reward they receive is neither up to their level of investment in labour and time nor is it equal to that of their male counterparts (Sharma 2020). According to the ILO study, the RMG industry tends to rely on low-paid female labour to compete and maximise profits in a highly competitive global market (ILO 2020). This statement alone shows how deliberately discriminatory this industrial sector is.

Tasks in the RMG factories are generally distributed based on gender in Bangladesh’s garments sector, and most of the working circumstances for women employees are determined by this (ILO, 2020). Most typically, women work as helpers, machinists, and, less frequently, as line supervisors and quality controllers (Ahmed, 2023). From data collected within factories, four out of every five production line workers are female, while just one in twenty supervisors is a woman (Heath, Mobarak 2014). Rahman (2022) writes that the percentage of women in managerial positions in the RMG sector has increased from 6 per cent to 12 per cent. This has been due to some training initiatives supported by international organizations. However, according to Ahmed (2023), access to managerial positions and higher-paying white-collar jobs is discriminated against for women. She further writes that as the burden of household work disproportionately falls more on women, the number of workers they can dedicate to work is also lower. Thereby, they also have a lesser inclination to opt for management positions (Ahmed, 2023). Meaning that due to the fact that women have to manage the bulk and burden of housework, they are less inclined to attempt managerial positions and opt for lower-paying work due to time constraints and the pressures and challenges of housebound activities.

As to payment, it is not globally uncommon that women in many sectors receive less pay than men. Farber (2017) gives three reasons for this: the ‘penalty’ of motherhood, the inability to negotiate ‘the right way’ and how they are treated when attempting to negotiate, and employer bias, where the employer knowingly or unknowingly undervalues a woman’s work. Women RMG workers in Bangladesh face all three of these hurdles. As seen, factories prefer to keep women in jobs that pay less. A 2021 study on the gender wage gap that used the administrative records of over 80,000 workers in 70 RMG factories in Bangladesh found an overall wage gap of 20 per cent of which more than half was due to the ‘overwhelming’ predominance of men in managerial roles (Menzel, Woodruff, 2021). In factory areas where women are a majority of the workers, such as in the sewing/floor areas, the same study found that the wage gap was 8 per cent. As regards impending motherhood and maternity leave, one study shows that the women workers’ knowledge of maternity leave and maternity benefits was inadequate, as was the accommodation provided by factories for pregnant workers (Awaj, 2019). In March 2021, it was reported that the IndustryAll Bangladesh Council had demanded from those in charge an assurance of six months of full-paid maternity leave for all female workers. The fact that this is still an issue shows that women are still being discriminated against for ‘motherhood’ in the 21st century.

The third Principle deals with ensuring the health, safety, and well-being of all workers. Workplace hazards can be broadly divided into five groups: (a) ergonomic hazards; (b) physical hazards; (c) psychological hazards; (d) mechanical hazards; and (e) chemical hazards (Raihan, Chowdhury 2023). According to Kabir (2019), it is ‘evident that RMG workers in South and Southeast Asia are the most affected by the unhygienic and unsafe nature of their workplace conditions’. In 2017, the ILO conducted a baseline survey on RMG workers with the South Asian Network on Economic Modelling. It studied the lives of 2,184 workers from 111 RMG factories and found that the three most pressing health issues the workers suffered from were thirst (68.5 per cent), hunger (53.2 per cent), and headaches (43.63 per cent) and that 7.05 per cent suffered long-term illnesses such as gastric ulcers and joint pains (Raihan et al. 2019). Another similar survey, conducted by ActionAid in 2019, of 200 women workers found that 90 per cent had experienced negative health impacts at work. These included exhaustion (78 per cent), severe back pain (57 per cent), and injuries to hands and feet (46 per cent), eyesight issues (36 per cent) (ActionAid, 2019).

‘Health, safety, and well-being’ can definitely extend to mental health and well-being. Given the discrepancies in the treatment of male and female workers, it is clear that women are already suffering some level of stress in the factory workplace. However, there is another side to this that has direct links to patriarchy, discrimination, and the poor treatment of women. This is sexual harassment and violence, and it is widely reported that women RMG workers face both. These contribute to the lack of empowerment opportunities for women in the RMG sector. In 2023, a Solidarity Centre report identified the kinds of gender-based violence female RMG workers suffer. The study showed that 45 per cent workers faced sexual harassment and violence, 22 per cent psychological, 17 per cent verbal abuse, 9 per cent economic and 7 per cent physical abuse and violence. Moreover, 89 per cent of the women in the study said that they had mental breakdowns due to such experiences, while 83 per cent said they had lost interest in their jobs. It is quite obvious that sexual harassment in the RMG workplace is a continuous violation, and its consequences leave both physical and mental pain and negate any opportunities for empowerment.

The fourth Principle towards empowerment is to provide women with training, education, and professional development. In 1978, 130 trainees were sent to South Korea from Bangladesh to embark on a training programme on how the RMG industry is run and how garments are manufactured. Eighteen of the 130 trainees were women (Khan, 2015). Today, training for female RMG workers is conducted in Bangladesh, mainly conducted and financed by international organisations, based on the recognition that women workers have low literacy levels and little control over their working conditions (H&M Foundation, 2020; UN Women Asia-Pacific). Training is also necessary to ensure that women are able to cope with the possibilities of automatons replacing them in the production line. Training is, however, not consistent across factories. A study of 111 factories conducted by SANEM (2019) for the ILO shows that introductory training of workers is either not carried out or is incomplete or improperly conducted in many factories. The same study shows that a majority of those who have received such training are male workers. But what about women’s training for managerial levels in the factory? For their professional development? Are there women in leadership positions on the factory floor? According to Islam and Jantan (2017), ‘In Bangladesh, the majority of the top managers are male, as evidenced by the report of the ILO (2015), which found women hold only 5.4 per cent leading positions in the organisations. Some reasons for this were highlighted in a study conducted by Matsuura’s (2020) and included the fact that supervisors or line chiefs are required to work overtime after regular working hours, and women had to go home and do housework and tend to children; women feared losing friends and peers if they advanced to supervisory roles; men were unable to accept the fact that women would be their supervisors; and women lack confidence in their abilities to manage male workers. Patriarchal traits of control, dominance, and position are clearly seen in the above reasons.

It is quite clear that what mainly drives the choice to work in the RMG sector is financial necessity. After a study of the lives of 17 female RMG workers, Al Mamun et al. (2022) surmised that paid RMG employment in Bangladesh has significant positive impacts on female workers’ economic, social, and psychological empowerment. Their findings also pointed to the suggestion that female RMG workers have gained economic capacity, along with some autonomy, freedom of mobility, increased decision-making power, a greater sense of self-esteem, job skills and experience, and consciousness about their rights to make choices (Al Mamun, Hoque, 2022). Despite the positive impacts, the ‘curse’ of patriarchy loomed over the workers private lives, as shown by the 2022 study, which highlights the fact that: salaries were kept by some of the women in a common family fund and some women had to seek the permission of their husband’s before sending money to help their parents; despite working long hours, some women states that they had to do all the housework alone; some women had to leave their children behind with family members in the village because of the long working hours; some women stated that people back in their village were defaming them for working outside the home; and that women with low levels of education were not moving up the ladder.

A recent study supported by the German agency GTZ shows that in 2021, only 53.65 per cent of garment workers were women (Rahman et al., 2023). In 2023, a Bangladesh Bureau of Statistics survey reported that the number of women RMG workers had declined by 10.68 per cent in the span of four years. The same study quotes that the number of female workers makes up 46.18 per cent of the workforce. This is a significant drop in numbers. This shows that although women have been enticed into financial freedom from RMG factories, they have not been able to find the atmosphere or means by which they may be truly empowered in their professional lives either. When garment industries commenced work in the 1980’s, employment opportunities were very limited for women from lower income groups (Rahman et al., 2023). As a result, the number of female workers was high.

What is required for ‘empowerment’? According to Papa Seck, chief of the UN Women’s Research and Data Section, ‘There is no empowerment without rights, so women’s empowerment needs to be anchored in human rights, which provide a universal framework for monitoring. For women to be empowered, they need resources, respect, and a voice. This requires redressing women’s socioeconomic disadvantage, addressing stereotyping, stigma, and violence, and strengthening women’s agency, voice, and participation.’ Putting this all into the framework of women workers in the RMG sector, we see that though women are working and seeking employment, this may be an exercise of their rights, or it may be something that is forced upon them by a father or husband. It may be that they had no choice in the matter. Regardless of whether it is an exercise of their individual right to work, they are still not treated with respect and dignity in the workplace, their resources as regards wages and healthcare remain inadequate, and they have no guarantee of long-term employment. As regards the addressing and redressing of stereotypes, stigma, and violence— and even socioeconomic disadvantages — these issues go far beyond the factory walls and boundaries. These challenge patriarchy and the social structure as a whole. You can take a male factory manager or lineman out of the factory, but you cannot take the patriarchal mindset out of him.

Verbal and sexual abuse, the lack of promotion of qualified women workers, unequal pay, unhygienic conditions for women workers, and the reluctance towards pregnant and new mothers — all point towards a greater, social problem that, unless addressed, will never allow women to find empowerment. Even when they are home, women RMG workers need to do all the housework and even suffer domestic violence. Women are leaving the factories due to conditions that in no way enable them to continue work outside the home. These issues show that women have yet to break the bonds of patriarchy, despite finding employment and, perhaps, economic freedom.

The theme of International Women’s Day 2024 is ‘Invest in Women: Accelerate Progress’. What then needs to be done to make the RMG sector a safe space for women’s empowerment? There is no doubt that empowerment is required for progress. There has to be recognition from factory owners, factory management, and definitely foreign buyers that women workers are not merely dispensable parts of the factory, working to benefit only buyers and owners. The guidelines of the Women’s Empowerment Principles need to be followed and mechanisms put in place to ensure full implementation for the benefit of all women workers. This can only be done if women RMG workers are given the respect, security, and facilities they deserve in order to work with dignity. However, that is definitely not enough. The root cause of why women are held back from becoming truly empowered anywhere needs to be addressed as well. Social change is required, and respect for gender, qualification, and education all need to come in a single package. Given that patriarchy is firmly entrenched in the very fibre of Bangladeshi society, challenging patriarchy needs to be done in small doses, and it is the responsibility of families, workplaces, educational institutions, and the government to ensure these steps are implemented. Merely showing data on how many women are employed in various public sectors or are enrolled in academic institutions in no way means that women have been empowered or that they are not facing any social or familial backlash.

Saira Rahman Khan is a professor of law, BRAC University.

www.newagebd.net

www.newagebd.net