Saif

Senior Member

- Joined

- Jan 24, 2024

- Messages

- 17,384

- Likes

- 8,373

- Nation

- Residence

- Axis Group

Bangladesh’s growing prowess in RMG makes Chinese investors upbeat

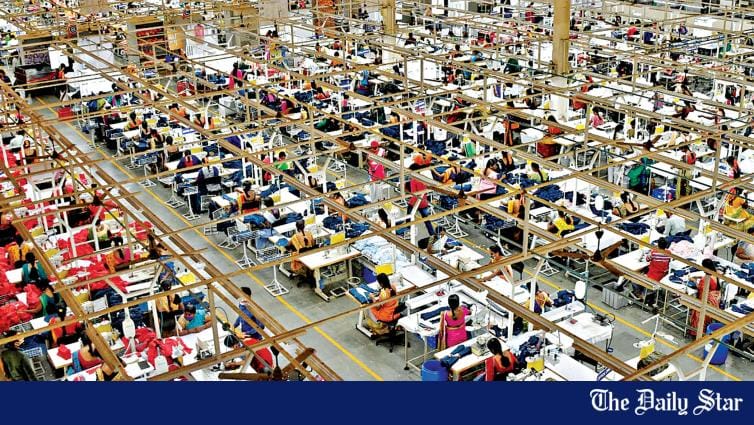

Chinese textile and garment entrepreneurs are bullish about Bangladesh as the country cements its position as a top supplier of apparel items, evidenced from a healthy flow of orders from international clothing retailers and brands.

Bangladesh’s growing prowess in RMG makes Chinese investors upbeat

Customers inspect products at an exposition on yarn, fabric and denim items at the International Convention City Bashundhara in Dhaka yesterday. More than 400 companies from 15 countries have set up 550 booths to showcase textile and garment items at the event. Photo: Sk Enamul Haq

Chinese textile and garment entrepreneurs are bullish about Bangladesh as the country cements its position as a top supplier of apparel items, evidenced from a healthy flow of orders from international clothing retailers and brands.

On the back of higher demand for fabrics, yarns, chemicals, dyes, and capital machinery used in the textile and garment sectors, China has turned into the largest supplier for Bangladesh.

Bangladesh imports nearly $20 billion worth of goods, including fabrics, from China, said industry people.

The reliance on the second-biggest economy in the world is growing since local weavers can only meet 40 percent of the requirement for woven fabrics. The remaining 60 percent is met through imports, mainly from China and India.

Owing to a brighter outlook of Bangladesh and the rising cost of production in China amid a dearth of skilled workers, Chinese investors are flocking to the country and investing in the textile and garment sectors.

At the same time, Chinese fabric sellers are targeting export-oriented garment factories which have been receiving an increased volume of orders from global retailers and brands.

A good number of Chinese textile and garment manufacturers are taking part in the 21st Dhaka International Yarn and Fabric Show 2024 and the 6th Denim Bangladesh 2024 International Expo at the International Convention City in the capital's Bashundhara.

CEMS Global and CCPIT-TEXT of China have jointly organised the exhibitions, where 410 companies from 15 countries have set up 550 booths to showcase textile and garment items. The event will continue until March 9.

"2023 was not good for business given higher inflation in Europe and the US. Now, a lot of orders are coming to Bangladesh and orders are expected to increase further in the near future," said Yong Zhang, general manager of Jinlite, an outerwear manufacturer, which has a factory in the Mongla Export Processing Zone.

Zhang set up the factory in 2018 with a 100 percent Chinese investment to meet demand for outerwear, rainwear, activewear and jackets in Europe and the US. Currently, the factory exports garment items worth more than $20 million annually.

Melody Zhou, sales manager at Top One Down & Feather Co Ltd, said their factory is witnessing a spike in demand for high-end jackets made from duck feathers.

She was the first to introduce the products in Bangladesh and the response from customers has been high.

"Bangladesh has a lot of garment factories and the business opportunity is high."

Aileen, a Chinese entrepreneur who has been selling viscose in Bangladesh, for the last nine years, agrees.

"Sales are good and the demand is rising."

At the inauguration of the showcase, Faruque Hassan, president of the Bangladesh Garment Manufacturers and Exporters Association, said Bangladesh has the highest number of green garment factories in the world and this has brightened the image of the sector and the country and given a boost to buyers' confidence.

"2024 will turn out as a good year for us as retailers and brands are coming up with a higher volume of orders."

Bangladesh, the second-largest apparel supplier globally, is already the biggest denim exporter in Europe and the US, which highlights the sector's strength.

Amin Helaly, senior vice-president of the Federation of Bangladesh Chambers of Commerce and Industry, said Bangladesh imports more than $10 billion worth of fabrics from China per year.

"So, an opportunity has been created for Chinese investors to invest in the textile and garment sector in the country."

Lokman Hossain Miah, executive chairman of the Bangladesh Investment Development Authority, also spoke at the inauguration.