Saif

Senior Member

- Joined

- Jan 24, 2024

- Messages

- 15,828

- Likes

- 7,983

- Nation

- Axis Group

Bangladesh retains second largest RMG exporter ranking amid modest growth

The global apparel market expanded to $557.50 billion in 2024, reflecting a 7.08 per cent year-on-year growth from $520.62 billion, according to the latest data released by the World Trade Organization (WTO). This rebound signals a continued recovery in global demand despite ongoing geopolitical te

Apparel market grows to $557.50 billion

Bangladesh retains second largest RMG exporter ranking amid modest growth

Jasim Uddin

Published :

Jul 08, 2025 11:31

Updated :

Jul 08, 2025 11:31

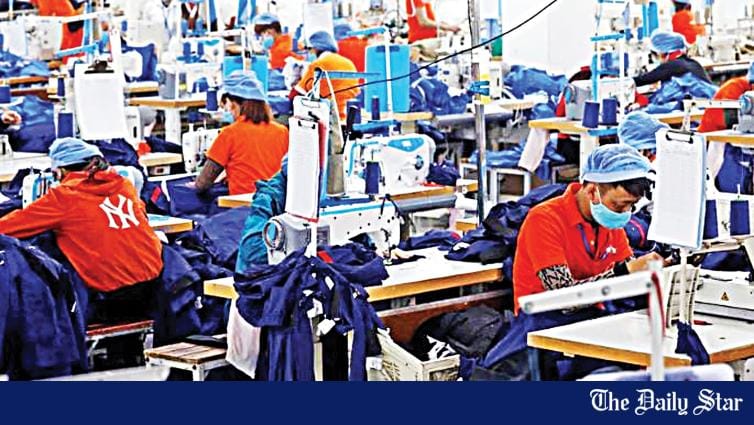

The global apparel market expanded to $557.50 billion in 2024, reflecting a 7.08 per cent year-on-year growth from $520.62 billion, according to the latest data released by the World Trade Organization (WTO). This rebound signals a continued recovery in global demand despite ongoing geopolitical tensions, rising production costs, and lingering post-pandemic challenges.

China holds the lead, Bangladesh remains in the second place

China retained its position as the world’s leading apparel exporter, registering $165.24 billion in exports—up slightly by 0.30 per cent. Bangladesh held firmly to the second spot with export earnings of $38.48 billion, though its growth remained modest at 0.21 per cent.

Vietnam strengthened its position as a formidable competitor in the global apparel landscape. It posted the highest growth among the top exporters at 9.34 per cent, reaching $33.94 billion in apparel exports.

Other major exporters show mixed trends

Turkey reported exports worth $17.91 billion, while India stood at $16.36 billion. Cambodia, Pakistan, Indonesia, and the United States recorded apparel exports of $9.89 billion, $9.28 billion, $8.73 billion, and $7.00 billion, respectively.

Export growth across these countries varied significantly, ranging from a sharp 24.19 per cent rise to a contraction of 4.42 per cent, underlining the shifting dynamics of global sourcing, reshoring trends, and trade policy uncertainties.

Market share by the country

China accounted for the largest share of global apparel exports at 29.64 per cent, followed by Bangladesh with a 6.90 per cent share.

However, china has 31.64 per cent and Bangladesh holds 7.38 per cent shares in 2023.

Vietnam increased to 6.09 per cent from 5.96 per cent, while Turkey and India held 3.21 per cent and 2.94 per cent shares respectively.

Among other top exporters countries- Cambodia held 1.77 per cent share, Pakistan (1.66 per cent), Indonesia (1.57 per cent), and the USA (1.26 per cent) rounded out the top contributors.

Bangladesh’s challenges and opportunities

Commenting on the data, Mohiuddin Rubel, Former Director of BGMEA and Managing Director of Bangladesh Apparel Exchange, said, “While Bangladesh remains the second-largest apparel exporter globally, the negligible growth in 2024 signals the need for strategic reforms and diversification. Our competitiveness is being tested not only by Vietnam’s dynamic growth but also by the evolving demands of buyers and heightened sustainability expectations.”

He said that Bangladesh must invest in innovation, technology, upskilling, and climate resilience to retain its competitive edge in a rapidly transforming global supply chain.

Despite global headwinds, the apparel trade is showing resilience. However, rising inflation in key markets, shifting sourcing preferences, and regulatory compliance, particularly in sustainability and due diligence, are likely to shape the next phase of industry transformation, he added.

For Bangladesh, maintaining its foothold in traditional markets while exploring opportunities in non-traditional destinations such as Japan, South Korea, Australia, and the Gulf region will be crucial for sustaining growth in the coming years.

Bangladesh retains second largest RMG exporter ranking amid modest growth

Jasim Uddin

Published :

Jul 08, 2025 11:31

Updated :

Jul 08, 2025 11:31

The global apparel market expanded to $557.50 billion in 2024, reflecting a 7.08 per cent year-on-year growth from $520.62 billion, according to the latest data released by the World Trade Organization (WTO). This rebound signals a continued recovery in global demand despite ongoing geopolitical tensions, rising production costs, and lingering post-pandemic challenges.

China holds the lead, Bangladesh remains in the second place

China retained its position as the world’s leading apparel exporter, registering $165.24 billion in exports—up slightly by 0.30 per cent. Bangladesh held firmly to the second spot with export earnings of $38.48 billion, though its growth remained modest at 0.21 per cent.

Vietnam strengthened its position as a formidable competitor in the global apparel landscape. It posted the highest growth among the top exporters at 9.34 per cent, reaching $33.94 billion in apparel exports.

Other major exporters show mixed trends

Turkey reported exports worth $17.91 billion, while India stood at $16.36 billion. Cambodia, Pakistan, Indonesia, and the United States recorded apparel exports of $9.89 billion, $9.28 billion, $8.73 billion, and $7.00 billion, respectively.

Export growth across these countries varied significantly, ranging from a sharp 24.19 per cent rise to a contraction of 4.42 per cent, underlining the shifting dynamics of global sourcing, reshoring trends, and trade policy uncertainties.

Market share by the country

China accounted for the largest share of global apparel exports at 29.64 per cent, followed by Bangladesh with a 6.90 per cent share.

However, china has 31.64 per cent and Bangladesh holds 7.38 per cent shares in 2023.

Vietnam increased to 6.09 per cent from 5.96 per cent, while Turkey and India held 3.21 per cent and 2.94 per cent shares respectively.

Among other top exporters countries- Cambodia held 1.77 per cent share, Pakistan (1.66 per cent), Indonesia (1.57 per cent), and the USA (1.26 per cent) rounded out the top contributors.

Bangladesh’s challenges and opportunities

Commenting on the data, Mohiuddin Rubel, Former Director of BGMEA and Managing Director of Bangladesh Apparel Exchange, said, “While Bangladesh remains the second-largest apparel exporter globally, the negligible growth in 2024 signals the need for strategic reforms and diversification. Our competitiveness is being tested not only by Vietnam’s dynamic growth but also by the evolving demands of buyers and heightened sustainability expectations.”

He said that Bangladesh must invest in innovation, technology, upskilling, and climate resilience to retain its competitive edge in a rapidly transforming global supply chain.

Despite global headwinds, the apparel trade is showing resilience. However, rising inflation in key markets, shifting sourcing preferences, and regulatory compliance, particularly in sustainability and due diligence, are likely to shape the next phase of industry transformation, he added.

For Bangladesh, maintaining its foothold in traditional markets while exploring opportunities in non-traditional destinations such as Japan, South Korea, Australia, and the Gulf region will be crucial for sustaining growth in the coming years.