Saif

Senior Member

- Joined

- Jan 24, 2024

- Messages

- 16,835

- Likes

- 8,152

- Nation

- Residence

- Axis Group

Cash subsidy for exports surges. Only garment yields expected results

The government’s cash incentive against export receipts has soared over the years although many sectors could not make their mark in the global market, bringing in limited results for the government’s diversification initiative.

Cash subsidy for exports surges. Only garment yields expected results

The government's cash incentive against export receipts has soared over the years although many sectors could not make their mark in the global market, bringing in limited results for the government's diversification initiative.

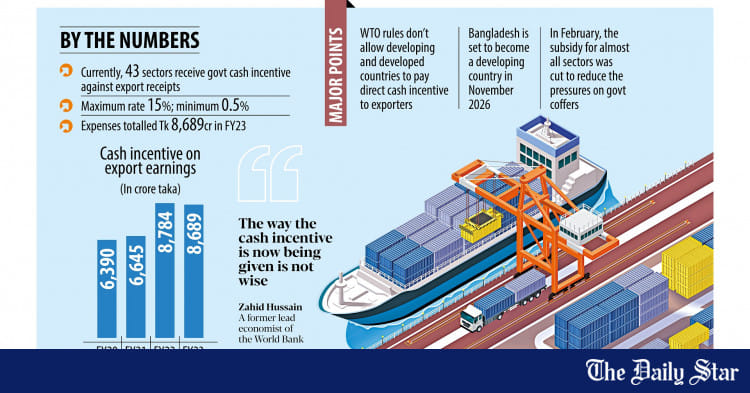

Currently, 43 sectors receive taxpayer-funded cash support, with the maximum rate standing at 15 percent and the minimum rate at 0.5 percent.

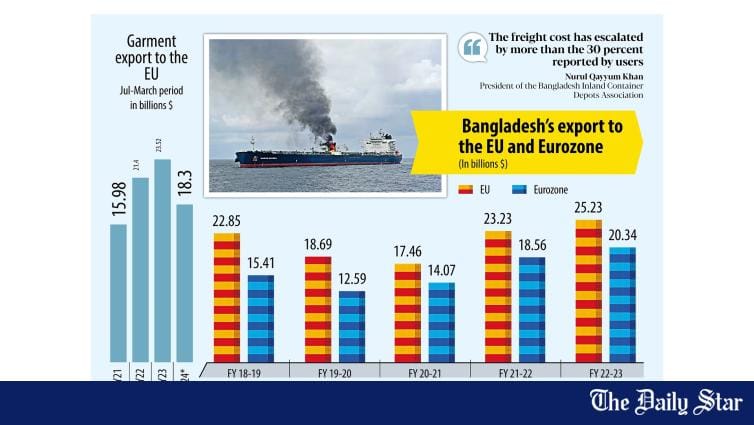

Of them, only the garment sector has consistently fared well, turning Bangladesh as the second-largest apparel supplier in the world. The sector accounts for about 85 percent of the country's exports as well.

The government has spent thousands of crores of taka over the years to help exporters become competitive in international trade. The subsidy amount stood at Tk 8,689 crore in the last financial year of 2022-23, slightly down from Tk 8,784 crore from a year prior, Bangladesh Bank data showed.

However, the generous handout can't be continued after 2026 since World Trade Organisation (WTO) rules don't allow developing and developed countries to pay direct cash incentives to exporters. Bangladesh is set to become a developing country in November 2026.

The imminent graduation and persisting pressure on the coffer amid low tax collections prompted the government to cut the subsidy for almost all sectors in February with a view to bringing down the rates gradually and protecting exporters from any shock that may emanate in the event of a sudden withdrawal of the cash aid.

The highest cash incentive rate has been reduced to 15 percent from 20 percent for most sectors. Only four sectors – diversified jute products, vegetables, fruits and products in the agro-processing sector, potatoes, and halal meat and processed meat exporters -- will qualify for the top rate.

Despite immense potential and direct cash assistance, sectors such as jute and jute goods, leather and leather goods, and agro-processing and frozen foods have not been able to emulate the feat achieved by the garment sector.

Even, results are mixed within the garment sector. For example, Bangladesh is still strong in cotton fibre garment items although the world has moved towards non-cotton items. Furthermore, apparel items produced from artificial materials fetch better prices than those made from the natural fibre.

Speaking to The Daily Star, Zahid Hussain, a former lead economist of the World Bank, said the way the cash incentive is now being given is not wise.

"The way should be reconsidered because many sectors could not produce positive outcomes though the money was spent."

If Bangladesh, as a developing nation, provides direct cash incentives on export receipts, disputes regarding compliance will arise, he said.

Hussain said the diversification in the export sector did not take place except in the garment industry despite spending the money. Even corruption took place in the management of cash incentives.

"Therefore, if the incentive is retained for any sectors after the LDC graduation in different forms, the eligibility of sectors should be assessed."

SM Mannan Kochi, president of the Bangladesh Garment Manufacturers and Exporters Association, said they had already held meetings with finance ministry officials and called for the continuation of incentives after the LDC graduation since countries such as India and China pay such incentives under different names.

"Many countries are giving the incentive in the name of technology upgradation or skills development funds."

According to the business leader, there are numerous small and medium enterprises and emerging sectors in Bangladesh that are not strong enough financially to cope up with the potential challenges in the post-LDC era.

"The cost of doing business is increasing because of the power tariff hike, so the government should continue the incentive even after the graduation."

The government's cash incentive against export receipts has soared over the years although many sectors could not make their mark in the global market, bringing in limited results for the government's diversification initiative.

Currently, 43 sectors receive taxpayer-funded cash support, with the maximum rate standing at 15 percent and the minimum rate at 0.5 percent.

Of them, only the garment sector has consistently fared well, turning Bangladesh as the second-largest apparel supplier in the world. The sector accounts for about 85 percent of the country's exports as well.

The government has spent thousands of crores of taka over the years to help exporters become competitive in international trade. The subsidy amount stood at Tk 8,689 crore in the last financial year of 2022-23, slightly down from Tk 8,784 crore from a year prior, Bangladesh Bank data showed.

However, the generous handout can't be continued after 2026 since World Trade Organisation (WTO) rules don't allow developing and developed countries to pay direct cash incentives to exporters. Bangladesh is set to become a developing country in November 2026.

The imminent graduation and persisting pressure on the coffer amid low tax collections prompted the government to cut the subsidy for almost all sectors in February with a view to bringing down the rates gradually and protecting exporters from any shock that may emanate in the event of a sudden withdrawal of the cash aid.

The highest cash incentive rate has been reduced to 15 percent from 20 percent for most sectors. Only four sectors – diversified jute products, vegetables, fruits and products in the agro-processing sector, potatoes, and halal meat and processed meat exporters -- will qualify for the top rate.

Despite immense potential and direct cash assistance, sectors such as jute and jute goods, leather and leather goods, and agro-processing and frozen foods have not been able to emulate the feat achieved by the garment sector.

Even, results are mixed within the garment sector. For example, Bangladesh is still strong in cotton fibre garment items although the world has moved towards non-cotton items. Furthermore, apparel items produced from artificial materials fetch better prices than those made from the natural fibre.

Speaking to The Daily Star, Zahid Hussain, a former lead economist of the World Bank, said the way the cash incentive is now being given is not wise.

"The way should be reconsidered because many sectors could not produce positive outcomes though the money was spent."

If Bangladesh, as a developing nation, provides direct cash incentives on export receipts, disputes regarding compliance will arise, he said.

Hussain said the diversification in the export sector did not take place except in the garment industry despite spending the money. Even corruption took place in the management of cash incentives.

"Therefore, if the incentive is retained for any sectors after the LDC graduation in different forms, the eligibility of sectors should be assessed."

SM Mannan Kochi, president of the Bangladesh Garment Manufacturers and Exporters Association, said they had already held meetings with finance ministry officials and called for the continuation of incentives after the LDC graduation since countries such as India and China pay such incentives under different names.

"Many countries are giving the incentive in the name of technology upgradation or skills development funds."

According to the business leader, there are numerous small and medium enterprises and emerging sectors in Bangladesh that are not strong enough financially to cope up with the potential challenges in the post-LDC era.

"The cost of doing business is increasing because of the power tariff hike, so the government should continue the incentive even after the graduation."